Automated AI Visual Inspection Platform

Few-Shot Learning|Multi-SKU Changeovers | User-Friendly Low Code

Offering you a cost-effective, all-in-one solution to maximize automation value

High-Precision Pre-Trained Model

High-precision pre-trained model, coupled with its strong generalization ability, enables few-shot detection—especially excels at identifying defects in scenarios where both good and defective products lack fixed shapes, with only 5-20 good/defective samples needed for fine-tuning. It prevents costly rework/recalls from manual inspection misses and achieves 0% miss rate and 0.5–3% false positive rate across industries.

Simplified Deployment & Changeover

No professional algorithm expertise is needed for system deployment. The system can be up and running in just days. When switching to new products, there’s no need for re-algorithm development or re-sample annotation, cutting changeover time from days to hours. For even greater flexibility, operators can quickly configure the system via a visual interface with AI Copilot after basic training, requiring no technical skills.

Enhanced Quality Consistency & Inspection Efficiency

EVVR OS enables 24/7 continuous operation, maintaining stable detection performance even in long-shift, high-volume production with no efficiency drops from manual fatigue while maintaining zero inconsistency in quality standards. All products are inspected by the same logic and quality data is traceable for customer audits and internal quality reviews.

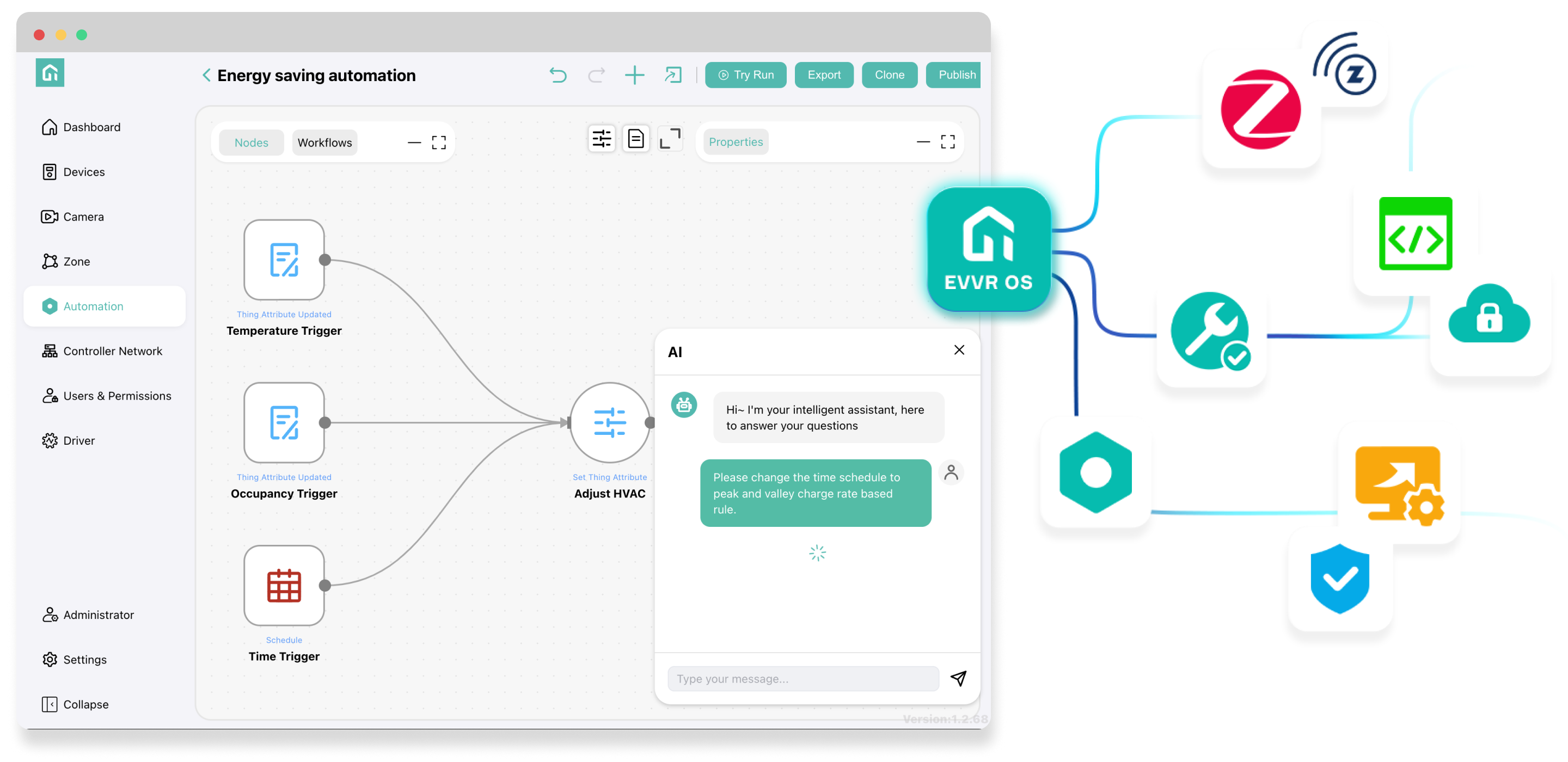

Multiple Protocols Support

EVVR OS is compatible with multiple IoT devices protocols, allowing seamless integration with your existing systems and efficient data exchange between devices and platforms. It supports HTTP, MQTT, Zigbee, Z-Wave, BLE, Modbus, OPC UA and BACnet.

Secure Local Processing

Businesses retain complete ownership of data through EVVR'S on-premise deployment. Sensitive operational data stays within your secure ecosystem, ensuring data privacy and full control without cloud dependency and latency delays.

Cross-System Integration & Rapid Development

EVVR OS provides open APIs and SDKs as tools for cross-system integration, connecting legacy systems, IoT devices and third-party platforms, enabling rapid development and seamless adaptation to your unique business requirements.

Reliable AI solutions for computer vision inspection & quality control

No need to start from scratch—EVVR OS integrates seamlessly with your existing systems and scales with your business. AI engine adapts to flexible manufacturing, enabling you to detect defects 70% earlier, respond faster and achieve 15-25% higher yield with pinpoint precision.

EVVR OS transforms how you inspect, produce and compete, turning complexity into profitability with smart, AI-driven vision.

PCB

In PCB manufacturing, missed defects (including micro-defects), insufficient detection accuracy and slow changeovers are pressing challenges in the industry. The false positive rate of traditional inspection is as high as 25% with defective products entering the market. For flexible production changeovers, rules-based machine vision systems fail to adapt to new defect patterns and appearance variations and manual programming takes days to adjust, resulting in daily downtime losses.

EVVR OS precisely addresses these pain points with AI technology: the rate of missed defects is nearly zero, and the false positive rate is strictly controlled below 2%. It can precisely and stably identify various defects even micro-defects. Equipped with few-shot learning and no-code adaptation, the changeover time is reduced drastically from days to hours. From substrate inspection, component placement to solder joint detection, it provides full-process real-time monitoring and rapid feedback for corrections.

EVVR helps PCB enterprises increase yield by 15%-25%, reduce defect-related rework costs by 60%, and improve production line utilization by 30%, enabling them to efficiently cope with production needs featuring multiple defect types, high-mix products, and fast-paced operations.

Automotive

In automotive production, mixed-model lines, micro-defect leaks, and assembly errors have become a major headache for factories. Furthermore, traditional solutions perform poorly in terms of high defect miss rates and lengthy changeover times of days to months when transitioning to new models.

EVVR OS addresses these "mistake, miss, mix" pains head-on with AI-powered innovation. Leveraging few-shot learning, it adapts to varioud vehicle models or new structures in minutes to hours with only 5-10 samples and eliminate manual programming. Its precision detection achieves near-zero miss rates and ≥99.8% recognition of micro-defects while ensuring 100% accuracy in identifying incorrect or missing components.

After adopting EVVR OS, manufacturers see tangible, transformative results: a 35% increase in production line utilization, a 60-75% reduction in rework costs, a 90% drop in recall risks, and an 80-90% shortening of new model launch cycles. EVVR OS empowers enterprises to tackle complex production demands with a more flexible, efficient and reliable solution.

Battery

In 2025, global power battery installed capacity for electric vehicles reached 1,046 GWh by November, a 32.6% year-on-year surge, exceeding the 1 TWh milestone for the first time. Looking ahead, battery industry will advances toward intelligent, automated, flexible technologies for excellence in quality control from cells to packs.

EVVR OS delivers battery-specific AI innovation with the ability to address quality control challenges such as large production volumes, countless process control points and complex defect types. Its few-shot learning adapts to ternary, LFP, solid-state batteries in hours (5-10 samples), no coding needed. Pre-trained model deliver 99.9% defect recognition accuracy. Tailored for battery production workflows, EVVR OS treamlines changeovers, slashes rework costs and ensures zero-compromise quality.

EVVR OS empowers factories to scale production efficiently, accelerate the deployment of new technologies, and maintain uncompromising quality standards. EVVR unlocks greater operational excellence, competitive advantage, and sustainable success alongside you every step of the way.

Pharmaceutical &Medical

In Pharmaceutical & Medical industry, manual quality checks are labor intensive and require time-consuming offline reviews. Meanwhile, traditional vision systems demand weeks of manual labeling and large annotated samples for detection.

EVVR automated vision solutions help address trained manpower shortage and maintain inspection consistency in 24/7 operation. EVVR Al vision platform leverages generalization capabilities to overcome traditional data scarcity, updating inspection parameters with minimized date collection and labeling expense. This enables manufacturers to achieve significant ROl and quickly adapt to evolving business needs, from new product launches to.changing regulatory requirements.

.png?v=1767689844369)

Create Your Automation with Low-Code Solutions

By a clik of drag and drop, your custom automations can be realized instantly. With EVVR OS, you can easily create and test your automation workflows by setting logic, dragging and dropping components instead of writing extensive codes. EVVR OS is an agreeable option for you to fast develop workflow, simplify maintenance and reduce R&D costs.

Few-Shot Learning

Instead of spending weeks collecting and labeling thousands of images, you can build a high-accuracy inspection model with as few as 20–30 sample images. Training cycles are reduced from weeks to days. When the production process changes, there’s no need for full retraining. EVVR OS supports incremental learning, allowing users to update the model with a few new samples and can learn anomaly detection using only good samples.This transforms AI inspection from a long, project‑based development effort into a fast, responsive deployment process, dramatically improving efficiency and cost effectiveness.

Flexible Product Switching

In multi-SKU, small-batch production, switching product types typically requires starting from scratch. Our built-in transfer learning engine solves this by reusing feature knowledge from pre-trained models. The new inspection workflow becomes production-ready with a small set of new product samples within days.This capability supports rapid expansion into new product categories and manufacturing scenarios, delivering unmatched flexibility and scalability for AI-driven quality control.

Text to Automation Flow

Instead of relying on complex programming or rigid rule-based setups, users can simply describe their requirements in natural language through the AI Pilot. The system parses the command, selecting camera parameters, models, thresholds and output logic for a full inspection workflow.This feature turns ideas into working automation, breaking technical barriers and making configuration intelligent, intuitive and fast.

Drag-and-Drop Creator

EVVR OS features a drag-and-drop visual editor that simplifies inspection workflow setup. You can configure modules, adjust parameters and preview results in real time without writing code.Engineers and production teams can design, deploy and fine-tune models directly on-site without requiring AI/programming expertise. EVVR OS serves as an advanced machine vision software for quality control and automation across various industrial and commercial applications. It detects and identifies misaligned parts in real time with high accuracy and prevents costly rework to boost productivity and profitability.

Advanced Visualization

EVVR OS offers interactive dashboards of real-time quality data through various real-time charts, graphs and UI elements. It enables teams to proactively identify deviations, monitor quality trends and make data-driven decisions for sustainable operations.

EVVR OS dashboards are highly customizable, allowing users to tail interfaces to specific roles and workflows. Dashboards can be assigned to specific users, ensuring that teams/individuals have appropriate access and receive relevant data.

White-label and Customized Solutions

EVVR OS supports full white-label (OEM/ODM) customization, enabling partners to brand the interface with custom logos, color schemes and tailored feature modules. Through open APIs and a flexible plugin framework, integrators can extend functionality, embed the core inspection engine into proprietary hardware or integrate it with existing MES/ERP systems.This flexibility helps users launch their own AI inspection products faster, cut development cycles and expand ecosystem while retaining full brand ownership.

Specification

Multi-platform Compatibility

Build separate Docker images for ARM and x86 architectures.

Ensure compatibility of the toolchain and libraries on both architectures.

Communication

MQTT

HTTP

P2P

Security

Encryption

Configuration for TLS/SSL support.

Authentication

Methods for user and device authentication (e.g., username/password, token-based authentication).

Download

FAQs

Don’t see your question answered below? Contact us today.

Can EVVR OS connect with the hardware and systems already in our production line, such as PLCs and MES systems?

Yes. On the hardware side, it is compatible with mainstream industrial cameras (e.g., Hikvision, Basler) and ring light sources. On the system side, it supports industrial protocols like Modbus, OPC UA and so on, which allows direct connection to PLCs. Meanwhile, it can upload inspection data (defect type, location, quantity) to MES systems in real time.

What makes EVVR OS different?

EVVR OS achieves higher defect detection accuracy using few-shot learning compared to competitors and solves diverse vision challenges with generalization ability.

Is it possible to customize workflows according to our specific business requirements?

Absolutely! Our platform’s drag-and-drop workflow editor can help you create customized workflows.

What kind of training and support are provided during implementation?

Based on the size and complexity of the project, our team would offer reasonable and suitable on-site training covering system operation, data analysis, and troubleshooting. Additionally, 24/7 remote support is available to ensure smooth implementation and long-term operation.

After deploying EVVR OS, how long does it usually take to recover the investment?

On average, the investment can be recovered within 6–9 months.

The key cost-saving areas include: ① Labor costs reduced by 90% (replacing 24/7 shift-based quality inspectors); ② Scrap losses reduced by 40% (intercepting bulk defective products in advance); ③ Production capacity increased by 15% (cutting changeover downtime by 80%).

Where can I download EVVR OS?

You can check with different editions to your needs via:

Can EVVR OS connect with the hardware and systems already in our production line, such as PLCs and MES systems?

Yes. On the hardware side, it is compatible with mainstream industrial cameras (e.g., Hikvision, Basler) and ring light sources. On the system side, it supports industrial protocols like Modbus, OPC UA and so on, which allows direct connection to PLCs. Meanwhile, it can upload inspection data (defect type, location, quantity) to MES systems in real time.

What makes EVVR OS different?

EVVR OS achieves higher defect detection accuracy using few-shot learning compared to competitors and solves diverse vision challenges with generalization ability.

Is it possible to customize workflows according to our specific business requirements?

Absolutely! Our platform’s drag-and-drop workflow editor can help you create customized workflows.

What kind of training and support are provided during implementation?

Based on the size and complexity of the project, our team would offer reasonable and suitable on-site training covering system operation, data analysis, and troubleshooting. Additionally, 24/7 remote support is available to ensure smooth implementation and long-term operation.

After deploying EVVR OS, how long does it usually take to recover the investment?

On average, the investment can be recovered within 6–9 months.

The key cost-saving areas include: ① Labor costs reduced by 90% (replacing 24/7 shift-based quality inspectors); ② Scrap losses reduced by 40% (intercepting bulk defective products in advance); ③ Production capacity increased by 15% (cutting changeover downtime by 80%).

The key cost-saving areas include: ① Labor costs reduced by 90% (replacing 24/7 shift-based quality inspectors); ② Scrap losses reduced by 40% (intercepting bulk defective products in advance); ③ Production capacity increased by 15% (cutting changeover downtime by 80%).

Where can I download EVVR OS?

You can check with different editions to your needs via:

High Compatibility

EVVR OS ensures compatibility with a wide range of IoT devices You can also deploy EVVR OS on existing devices via Docker for greater flexibility and integration.

.png?v=1761204891950)

.png?v=1761204819933)